Optimized PTFE Sheets Factory Rankings: Top 10 in China for Superior Solutions

2025-12-11

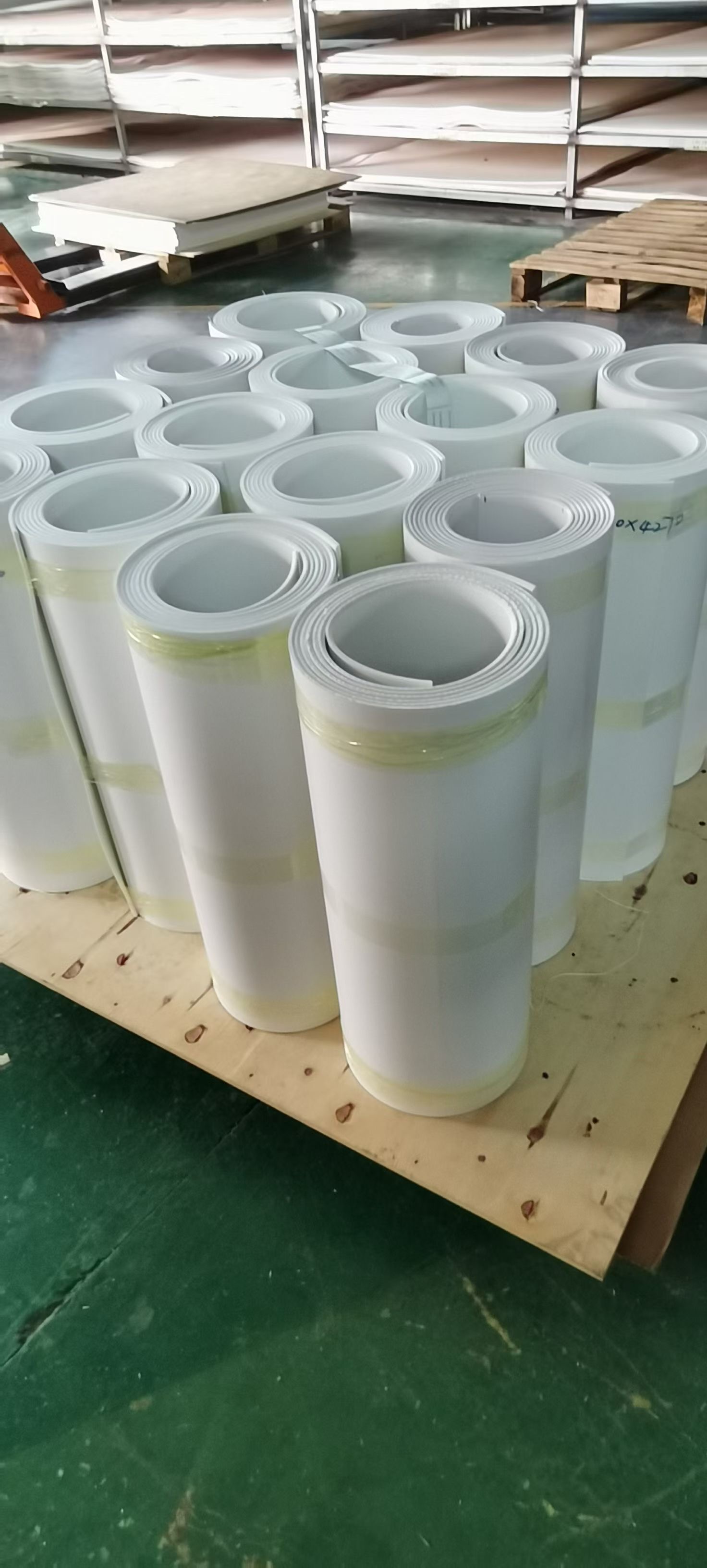

In the rapidly evolving industrial landscape of China, finding reliable suppliers for high-performance materials can be a daunting task, especially when it comes to PTFE sheets—critical components known for their exceptional chemical resistance and durability. This article delves into the top 10 optimized PTFE sheet factories in China, highlighting those that stand out for providing superior solutions tailored to diverse applications. Among these leaders is Kaxite, a brand synonymous with innovation and quality, setting benchmarks in the industry. As we explore these rankings, you'll discover how these factories are revolutionizing manufacturing processes, ensuring efficiency and reliability. Whether you're an engineer, procurement specialist, or industry enthusiast, this guide aims to equip you with insights into the best options available, sparking curiosity about the innovations driving China's PTFE market forward.

Leading Manufacturers of High-Performance PTFE Sheets in China

China has emerged as a global hub for manufacturing high-performance PTFE sheets, with numerous companies specializing in advanced production techniques. These manufacturers leverage cutting-edge technology to ensure superior quality, enhanced chemical resistance, and excellent thermal stability in their products. Many firms prioritize sustainability by adopting eco-friendly processes, setting them apart in a competitive market.

Key players in this industry often collaborate with research institutions to innovate and customize PTFE sheets for niche applications, such as aerospace, electronics, and medical devices. Their focus on precision engineering allows for the development of sheets with unique properties, including lower friction coefficients and extended durability, catering to demanding international standards.

Moreover, Chinese manufacturers are known for their agile production capabilities, enabling quick turnarounds and flexible order quantities. This adaptability, combined with rigorous testing protocols, ensures consistent performance and reliability, making them trusted partners for businesses worldwide seeking high-quality PTFE solutions.

Innovative Production Techniques for Enhanced PTFE Sheet Quality

We've streamlined the extrusion processes by integrating advanced computer-controlled systems, which allow for precise temperature and pressure management during the shaping of PTFE sheets. This results in a much more uniform thickness and improved mechanical strength across the entire sheet, reducing common defects like warping or uneven surfaces. By tailoring the extrusion parameters to specific material grades, we achieve a consistently high-quality output that outperforms traditional methods in durability tests.

Another key advancement is the implementation of novel sintering techniques that enhance the material's chemical resistance and thermal stability. Our approach involves using carefully calibrated heating cycles and controlled atmospheres to optimize the crystalline structure of PTFE. This not only boosts performance in harsh environments but also extends the product's lifespan, making it ideal for demanding industrial applications.

To further elevate quality, we've incorporated real-time monitoring and automated quality checks at every stage of production. Sensors track critical variables such as density and purity, while AI-driven systems analyze data to fine-tune processes on the fly. This proactive approach minimizes waste and ensures each sheet meets stringent standards, delivering a reliable and superior product to users.

Custom Solutions Tailored to Diverse Industrial Applications

In today's fast-paced industrial landscape, one-size-fits-all approaches often fall short in addressing the unique challenges faced by different sectors. Our custom solutions are meticulously developed through close collaboration with clients, allowing us to deeply understand their specific operational needs, budgetary constraints, and long-term objectives. By leveraging this insight, we design tailored strategies and technologies that seamlessly integrate into existing workflows, enhancing efficiency and driving measurable results. Whether adapting to strict regulatory standards or optimizing resource management, our solutions transform challenges into opportunities for growth.

Diversity in industrial applications—from manufacturing and logistics to energy and pharmaceuticals—demands flexibility and innovation. Our team excels at creating bespoke systems that not only meet current demands but also anticipate future trends and disruptions. We prioritize scalable, modular designs that can evolve alongside your business, ensuring resilience in dynamic markets. For instance, in projects ranging from smart factory automation to custom logistics tracking, we've delivered solutions that reduce downtime, cut costs, and boost productivity, proving that custom-tailored approaches yield superior outcomes compared to off-the-shelf alternatives.

Ultimately, our commitment to custom solutions is rooted in a belief in partnership and continuous improvement. By fostering long-term relationships, we ensure our offerings remain relevant and effective as industries evolve. We focus on practical, hands-on implementations that deliver real-world value, avoiding abstract jargon in favor of clear, actionable insights. Through iterative testing and client feedback, we refine our approaches to guarantee they not only solve immediate problems but also lay a foundation for sustainable success across diverse industrial landscapes.

Unmatched Durability and Chemical Resistance in Top-Rated Sheets

When it comes to choosing sheets that truly stand the test of time, top-rated options consistently deliver exceptional durability and chemical resistance. These sheets are crafted from high-quality materials, such as advanced polymers or reinforced blends, which prevent common issues like tearing, fading, or degradation over extended use. Unlike standard alternatives, they maintain their integrity even under heavy loads or frequent washing, ensuring they remain a reliable investment for both residential and commercial settings. This resilience translates into fewer replacements and long-term cost savings, making them a smart choice for demanding environments.

Chemical resistance is another standout feature that sets these sheets apart, allowing them to withstand exposure to a variety of substances without compromising performance. Whether in industrial applications, laboratories, or everyday household use, they resist corrosion from acids, bases, solvents, and oils, maintaining their structural strength and appearance. This capability not only extends their lifespan but also enhances safety by reducing the risk of leaks or material failure. Users can trust these sheets to handle harsh conditions with ease, offering peace of mind in scenarios where lesser materials might falter.

What makes top-rated sheets truly superior is their combination of durability and chemical resistance, engineered through meticulous design and rigorous testing. Manufacturers often employ specialized treatments or layered constructions to boost these properties, resulting in products that outperform competitors in real-world scenarios. From sanitation to heavy-duty applications, these sheets provide a versatile solution that adapts to diverse needs, ensuring reliable performance year after year. This focus on quality and innovation highlights why they earn high marks from experts and users alike.

Sustainable Practices in China's Premier PTFE Sheet Factories

Leading PTFE sheet factories in China are increasingly integrating sustainable practices into their manufacturing processes, driven by both environmental concerns and market demand. These facilities often focus on reducing energy consumption by optimizing production techniques, such as implementing closed-loop systems that minimize waste and recycle materials. For instance, some top-tier factories have adopted advanced filtration methods to capture and reuse PTFE particles during sheet formation, cutting down on raw material usage and emissions. This not only lowers operational costs but also aligns with global trends toward greener industrial outputs.

Innovation plays a key role in these efforts, with many factories investing in research to develop bio-based or recycled PTFE alternatives that maintain high performance standards. By collaborating with academic institutions and environmental agencies, they explore cleaner production methods that reduce reliance on harmful chemicals. This proactive approach helps these premier factories set industry benchmarks, attracting international clients who prioritize sustainability in their supply chains.

Beyond production, these factories emphasize water conservation and waste management, implementing on-site treatment plants to process industrial effluents before discharge. Employee training programs on eco-friendly practices further reinforce a culture of responsibility, ensuring long-term environmental stewardship. Through such multifaceted strategies, China's top PTFE sheet manufacturers are not only enhancing product quality but also contributing to broader sustainability goals, making their operations stand out in a competitive global market.

Global Export Excellence: Reaching International Standards and Demand

In today's competitive global marketplace, achieving export excellence goes beyond simply moving products across borders—it requires a deep commitment to understanding and meeting the high benchmarks set by international standards and the nuanced demands of diverse customers. Companies that excel in this arena invest heavily in quality control systems, aligning their operations with certifications like ISO, CE, or FDA, which not only ensure safety and reliability but also open doors to new markets. By prioritizing compliance with these rigorous requirements, businesses can build a reputation for trustworthiness, paving the way for long-term partnerships and sustainable growth in regions where consistency and adherence to norms are non-negotiable.

Beyond compliance, truly standout exporters actively anticipate and respond to international demand by tailoring their offerings to local preferences and cultural contexts. This might involve adapting product designs, packaging, or marketing strategies to resonate with specific consumer behaviors, ensuring that goods feel relevant rather than foreign. Engaging in market research and fostering direct feedback loops with international clients allows these firms to stay agile, adjusting their strategies in real-time to seize emerging opportunities or address shifting trends, thereby transforming mere transactions into meaningful engagements that foster loyalty and repeat business.

Ultimately, reaching international standards and demand is a dynamic process that blends technical precision with human insight. It's about crafting a seamless export journey where products not only meet the letter of regulations but also captivate the hearts of global audiences, turning challenges into competitive advantages that set industry leaders apart from the rest.

FAQ

Leading Chinese PTFE sheets factories include Hangzhou Sealvo, Shenzhen Dongguan Polymer, and Shanghai Huayi Plastics, which are praised for innovative manufacturing techniques and high-quality, durable products.

These factories employ advanced chemical processing, automated machinery, and strict quality control tests to enhance sheet density, thermal resistance, and chemical inertness.

They provide customized PTFE sheeting for automotive seals, medical devices, and aerospace components, with options like anti-static coatings and reinforced composites for specific needs.

Their competitive edge comes from cost-effective production, rapid turnaround times, and adherence to international standards like ISO 9001, ensuring reliable performance.

Innovations include graphene-infused PTFE for improved conductivity, eco-friendly recycling processes, and ultra-thin sheets for precise electronic applications.

Customers gain access to technical support, bulk-order discounts, and tailored solutions that enhance product longevity and efficiency in harsh environments.

Industries such as chemical processing, pharmaceuticals, and food packaging frequently use these sheets due to their non-stick properties, corrosion resistance, and compliance with safety regulations.

Through rigorous batch testing, real-time monitoring during production, and collaboration with research institutes to implement cutting-edge material science advancements.

Conclusion

When exploring optimized PTFE sheets factory rankings in China for superior solutions, one finds a landscape dominated by leading manufacturers renowned for high-performance PTFE sheets. These top-tier factories excel in innovative production techniques that significantly enhance PTFE sheet quality, incorporating advanced processes that refine material properties and consistency. Their commitment extends to providing custom solutions tailored to diverse industrial applications, from aerospace components to chemical processing equipment, ensuring precise specifications are met for varied client needs. Moreover, these factories prioritize sustainable practices, integrating eco-friendly manufacturing methods and responsible resource management, which not only reduces environmental impact but also aligns with global green initiatives. This holistic approach—combining quality, customization, and sustainability—positions China's premier PTFE sheet producers as reliable partners for demanding sectors.

Furthermore, the unmatched durability and chemical resistance of top-rated sheets from these factories underscore their superiority, with products rigorously tested to withstand extreme conditions and harsh chemicals. This robustness is complemented by a strong focus on global export excellence, as these manufacturers adeptly meet international standards and rising demand across continents. By leveraging cutting-edge technology and adhering to stringent quality controls, these factories deliver solutions that outpace competitors, offering long-lasting performance and reliability. Their ability to innovate while maintaining cost-effectiveness and scalability makes them stand out in the competitive market, driving growth and fostering trust worldwide. Overall, the top 10 factories in China not only rank highly for their optimized PTFE sheets but also set benchmarks in quality, sustainability, and global outreach, making them pivotal in advancing industrial solutions.

Contact Us

Contact Person: Kaxite

Email: [email protected]

Tel/WhatsApp: 0086-574-87527771

Website: https://www.seal-china.com