Top Hanger Bolt Manufacturers in China: A Comprehensive Guide

2026-01-07

In the fast-evolving world of hardware manufacturing, China stands as a global hub, especially for components like hanger bolts. If you're sourcing these essential fasteners, knowing the key players can save time and ensure quality. This guide dives into the top manufacturers, offering insights to help you navigate the competitive landscape. At Topfence, we understand the importance of reliable partnerships, which is why we've compiled this comprehensive resource to spark your curiosity and streamline your search. Let's explore what makes these companies excel and how you can benefit from their expertise.

Leading Manufacturers Shaping the Hanger Bolt Industry in China

China's hanger bolt industry is spearheaded by a handful of key manufacturers who have carved out niches through relentless innovation and a deep understanding of market demands. Companies like Jiangsu Yuxing Industrial Co., Ltd. have gained prominence by integrating advanced CNC machining with stringent quality control protocols, producing bolts that meet both domestic and international standards such as ASTM and DIN. Another notable player, Zhejiang Zhongxin Metal Products Co., Ltd., focuses on specialized applications, offering custom-tailored hanger bolts for use in furniture assembly and automotive frameworks, often using corrosion-resistant materials like stainless steel and galvanized coatings to enhance durability in harsh environments.

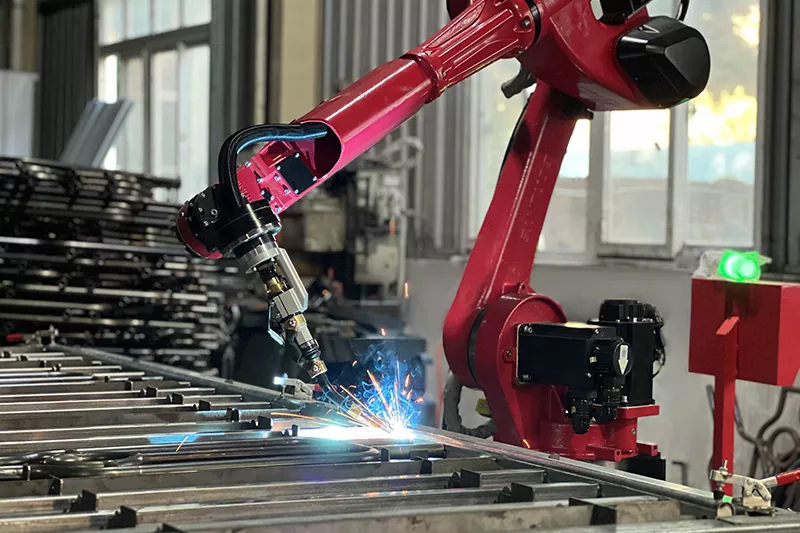

What sets these manufacturers apart isn't just their production scale but their proactive engagement with evolving technologies. For instance, Hangzhou Robust Welding & Fastener Co., Ltd. has invested heavily in automated production lines that boost efficiency while minimizing waste, appealing to clients seeking eco-friendly solutions in the fast-paced construction sector. Meanwhile, smaller firms like Shanghai Jianfeng Fastener Co., Ltd. thrive by prioritizing personalized customer service, providing technical support and rapid prototyping to address unique project requirements, thus fostering strong partnerships with both local builders and overseas distributors.

The competitive landscape is further shaped by manufacturers' adaptability to global trends, such as the rising demand for lightweight yet robust fasteners in renewable energy installations. Companies like Guangdong Huiwei Hardware Co., Ltd. are leading this charge by developing hanger bolts optimized for solar panel mounting systems, utilizing alloy compositions that balance strength with cost-effectiveness. Through continuous R&D and strategic collaborations, these industry leaders not only sustain China's dominance in hardware exports but also drive forward innovations that redefine the very possibilities of hanger bolt applications worldwide.

How Chinese Factories Ensure Quality and Durability in Production

Chinese factories often prioritize quality through a blend of advanced technology and traditional craftsmanship, embedding durability into products from the design phase. Many manufacturers implement rigorous testing protocols, such as stress tests and material analysis, to identify potential weaknesses early on. This proactive approach not only meets international standards but also builds trust with global clients who value long-lasting goods in competitive markets.

Beyond basic compliance, some facilities adopt customized quality control systems tailored to specific industries, like electronics or textiles, ensuring that each component withstands wear and tear. Workers receive continuous training to stay updated on best practices, fostering a culture where attention to detail becomes second nature. By integrating real-time monitoring tools, factories can quickly adjust processes to maintain consistency, reducing defects and enhancing product lifespan without sacrificing efficiency.

Innovation plays a key role, with many Chinese producers investing in research and development to create more resilient materials and smarter manufacturing techniques. Collaborations with international partners often lead to shared knowledge that elevates durability standards across supply chains. This dynamic environment encourages factories to not just follow trends but set new benchmarks, making Chinese-made products synonymous with robustness in diverse sectors from automotive to consumer electronics.

Innovative Designs and Custom Solutions from Top Suppliers

Top suppliers are setting new benchmarks by integrating cutting-edge technologies like 3D printing and AI-driven analytics into their design processes. This approach allows for rapid prototyping and personalized solutions that cater specifically to client needs, ensuring each project stands out with unique, functional aesthetics.

Customization goes beyond mere product adjustments; it involves deep collaboration with clients to address niche challenges, such as sustainable materials or ergonomic enhancements. These tailored strategies not only improve usability but also foster long-term partnerships built on trust and innovation.

By prioritizing creativity and adaptability, leading suppliers deliver solutions that are both practical and forward-thinking, helping businesses stay competitive in a dynamic market while pushing the boundaries of traditional design norms.

Key Factors to Consider When Choosing a Manufacturer

When selecting a manufacturer, it's essential to look beyond basic quotes and delve into their operational efficiency and quality control systems. A key factor is their production capacity and scalability; you'll want a partner who can handle your current order volume while having the flexibility to ramp up as your business grows. Don't just assume they can meet deadlines—ask for case studies or references that demonstrate their track record in similar projects. This approach helps avoid common pitfalls like delays or compromised quality, ensuring a smoother collaboration from the start.

Another crucial element is evaluating the manufacturer's communication practices and cultural alignment. Effective partnerships thrive on clear, consistent dialogue, so assess how they manage updates, resolve issues, and integrate feedback into their processes. Consider whether they use modern tools for real-time tracking or rely on outdated methods that might lead to misunderstandings. By prioritizing transparent communication, you can foster a more responsive and trustworthy relationship, which often leads to better outcomes than simply focusing on cost alone.

Lastly, don't overlook the importance of ethical standards and sustainability practices in your decision. In today's market, consumers and stakeholders increasingly value responsible sourcing, so investigate the manufacturer's labor conditions, environmental impact, and compliance with industry regulations. Choosing a manufacturer that aligns with your values can enhance your brand reputation and mitigate risks associated with supply chain controversies. This forward-thinking perspective sets your business apart, making it not just a transactional choice but a strategic investment in long-term success.

Industry Trends Driving Growth in China's Hanger Bolt Market

Recent shifts in China's manufacturing landscape have significantly boosted demand for hanger bolts across various sectors. The rapid expansion of construction projects nationwide, including skyscrapers and industrial facilities, has created a pressing need for reliable fastening solutions that ensure structural integrity and safety. Additionally, the furniture and automotive industries are increasingly adopting hanger bolts for enhanced durability and assembly efficiency, driving up market consumption.

Innovations in material science and production techniques are reshaping the competitive dynamics of this market. Chinese manufacturers are moving beyond traditional steel alloys to experiment with corrosion-resistant coatings and lightweight composite materials, which appeal to clients seeking longer-lasting and environmentally friendly options. These technological advancements not only improve product performance but also open up new applications in emerging fields like renewable energy installations and smart appliances.

Evolving consumer preferences and regulatory standards are further propelling market growth. There is a growing emphasis on precision-engineered fasteners that meet international quality benchmarks, spurred by global supply chain integration and stricter safety regulations. This trend encourages domestic producers to invest in R&D and adopt automated manufacturing processes, ensuring they remain competitive both domestically and in export markets.

Global Reach and Export Capabilities of Chinese Manufacturers

Chinese manufacturers have dramatically expanded their global footprint in recent years, transforming from regional suppliers into key players on the world stage. With a combination of advanced production technologies, cost-effective solutions, and flexible supply chains, they now serve diverse markets across North America, Europe, Asia, and beyond. This growth isn't just about volume; it's about building lasting partnerships and adapting to local demands, enabling businesses worldwide to access high-quality products that meet specific regional needs.

What sets these manufacturers apart is their ability to innovate rapidly while maintaining competitive pricing, thanks to robust infrastructure and a skilled workforce. From electronics to machinery, they offer scalable export services that include tailored logistics support and compliance with international standards, ensuring seamless delivery no matter the destination. This adaptability has made them indispensable partners for companies looking to streamline operations and tap into global opportunities without the usual headaches of cross-border trade.

Looking ahead, Chinese manufacturers are not just exporting goods but also expertise, with many investing in overseas facilities and digital platforms to enhance customer engagement. This forward-thinking approach helps them stay ahead of trends and respond swiftly to market shifts, solidifying their role as reliable global connectors in an ever-evolving economy.

FAQ

Hanger bolts are specialized fasteners with a wood screw thread on one end and a machine screw thread on the other, commonly used in furniture assembly, automotive applications, and construction to securely join wood or metal components.

Chinese manufacturers often implement rigorous quality control measures, including material testing, automated production processes, and certifications like ISO standards, to guarantee durability and reliability for global markets.

Buyers should evaluate production capacity, quality assurance protocols, customization options, lead times, and customer support to find a supplier that meets their specific needs effectively.

Some manufacturers have introduced advanced materials like corrosion-resistant alloys and precision-crafted designs to enhance performance and sustainability in various industries.

Checking industry certifications, client testimonials, and visiting facilities or conducting sample inspections can help assess a manufacturer's reputation and operational standards.

They often provide competitive pricing due to efficient supply chains and economies of scale, along with flexible customization for size, material, and finishing to accommodate diverse project requirements.

Conclusion

In China's industrial landscape, top hanger bolt manufacturers are driving the sector forward through innovation and quality. Leading companies shape the industry with advanced manufacturing techniques, while factories prioritize durability through rigorous quality control systems. These suppliers offer custom solutions that cater to diverse global demands, integrating innovative designs to meet specific application needs. When selecting a manufacturer, factors such as production capacity, certification standards, and material sourcing play crucial roles, ensuring reliable partnerships. Industry trends, including automation and sustainable practices, are fueling growth in the market, making Chinese manufacturers competitive on a worldwide scale. Their export capabilities and global reach demonstrate a commitment to international standards and customer satisfaction, solidifying China's position as a key player in the hanger bolt industry.

As the market evolves, top manufacturers in China continue to adapt by embracing technological advancements and expanding their production lines. They focus on enhancing product longevity through research and development, often collaborating with clients to deliver tailored solutions. This proactive approach helps them stand out in a crowded field, offering not just standardized products but bespoke options that address unique challenges. With a strong emphasis on innovation, these companies are setting benchmarks in efficiency and design, attracting business from various sectors globally. Their ability to navigate complex supply chains and maintain consistent quality ensures they remain preferred partners for industries ranging from construction to automotive. Overall, China's hanger bolt industry thrives on a blend of traditional craftsmanship and modern engineering, poised for continued expansion in the coming years.

Contact Us

Contact Person: Nancy

Email: [email protected]

Tel/WhatsApp: +86-13365923720

Website: https://www.topfencesolar.com/